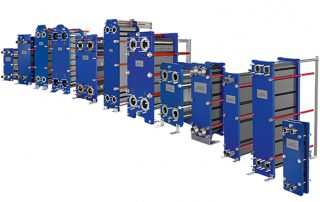

HEAT EXCHANGERS

Our heat exchangers are designed to meet the requirements of a wide range of applications such as refrigeration, comfort heating, industrial heating and cooling and the process industry.

Years of research and testing have resulted in the world’s most modern plate heat exchangers for heating and cooling applications. Packed full of features unique to Alfa Laval, these designs provide improved efficiency, reliability and serviceability.

Brazed Plate Heat Exchanger

Copper brazed plate heat exchangers provide efficient heat transfer with a small footprint. They are maintenance free, provide a long service lifetime and can withstand high temperatures and extremely high design pressures. They are used in a range of duties including cooling, heating, evaporation and condensing. Brazed plate heat exchangers are widely used in refrigeration plants. They are normally used to transfer heat from the refrigerant – the primary fluid – and from water or brine as the secondary fluid. Units in the Alfa Laval AC line of copper-brazed heat exchangers are mainly used as: Evaporators for dry expansion and cooling water Condensers for rejecting or recovering heat to water Economizers for cooling liquid refrigerant and super-heating vapour refrigerant. They can also be used [...]

Fusion Bonded

Fusion-bonded plate heat exchangers are made of 100% stainless steel and provide efficient heat transfer with a small footprint. They are maintenance free and provide a long service lifetime. They are suited in applications which put high demand on cleanliness, applications where aggressive medias such as ammonia are used or where copper and nickel contamination is not accepted. Can handle very high temperatures or extremely high pressures. The AlfaNova is the first plate heat exchanger in the world to be made completely of stainless steel – made possible by the unique active diffusion bonding technology patented by Alfa Laval. AlfaNova plate heat exchangers are made of 100% stainless steel, with the components fused together using a breakthrough technology that Alfa Laval has patented. This [...]

Semi Welded Plate Heat Exchanger

Alfa Laval Industrial semi-welded line handles most refrigerants and is particularly suitable for applications involving ammonia. Semi-welded heat exchangers are used in both organic and inorganic chemical processing when the chemicals involved limit the selection of gaskets that can be used or when the required design pressure makes fully gasketed plate-and-frame heat exchangers insufficient. The media passes through the welded channel facing the ring gasket sealing between the laser welded cassettes. Alfa Laval semi-welded heat exchangers employ the Alfa Laval RefTight™, a unique sealing system which guarantees high performance by positioning the laser weld on the outside of the ring gasket groove. The smooth ring gasket grove ensures equal sealing force over the entire porthole gasket. Equipped with well-designed features, Alfa Laval Industrial [...]

Gasketed Plate Heat Exchangers

The Industrial line’s versatility allows it to be designed and configured for applications ranging from relatively simple duties with low requirements to very demanding duties with the highest requirements on both performance and documentation. The products are used for heating, cooling, heat recovery, condensation, and evaporation. Equipped with well-designed features, the Industrial line of heat exchangers are easy to maintain and have a long service life. Some of the features available include: ClipGrip™ gasket – a glue free gasket with superior alignment that ensures a perfect seal and trouble-free maintenance. Glued gasket – a two-component, oven-cured epoxy glue keeps the gasket in place during any possible cleaning condition. CurveFlow™ distribution area – ensures full use of the heat [...]

Comfort Handbook