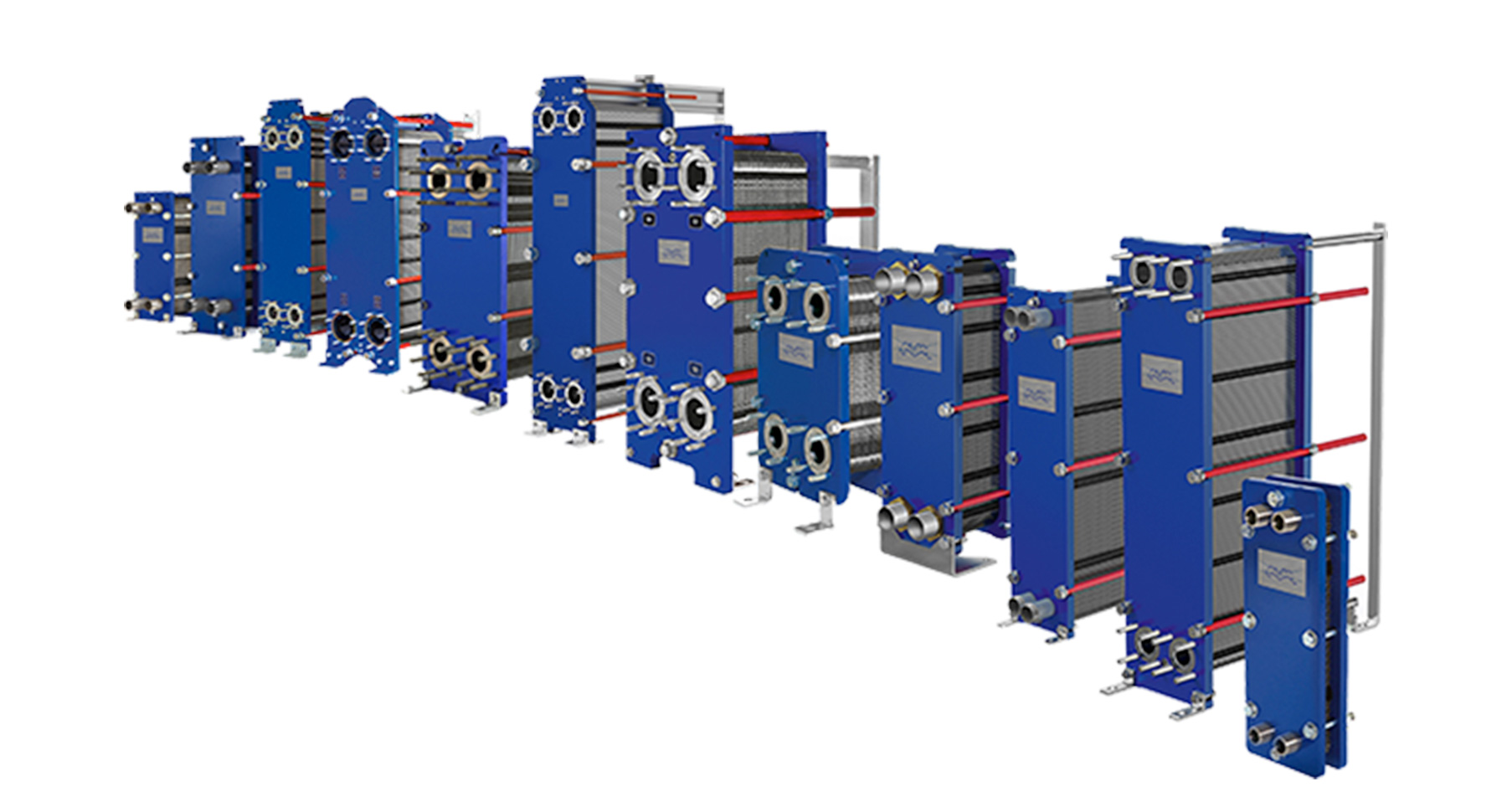

The Industrial line’s versatility allows it to be designed and configured for applications ranging from relatively simple duties with low requirements to very demanding duties with the highest requirements on both performance and documentation. The products are used for heating, cooling, heat recovery, condensation, and evaporation.

Equipped with well-designed features, the Industrial line of heat exchangers are easy to maintain and have a long service life. Some of the features available include:

- ClipGrip™ gasket – a glue free gasket with superior alignment that ensures a perfect seal and trouble-free maintenance.

- Glued gasket – a two-component, oven-cured epoxy glue keeps the gasket in place during any possible cleaning condition.

- CurveFlow™ distribution area – ensures full use of the heat transfer area and minimizes fouling.

Additionally, the pressure plate roller, the bearing boxes on the tightening bolts, and the 5 point alignment system with reinforced hangersmake opening and closing the heat exchanger quick and easy without the need for heavy tools or the risk of damaging the plates.

Alfa Laval Industrial line is quick and easy to modify if process parameters change. Our team’s expertise and the availability of parts bring you peace of mind.

Gasketed plate heat exchangers for modern requirements

Our Gasketed plate heat exchangers are optimizing heat transfer by large surfaces of corrugated plates drawing heat from one gas or liquid to the other. The high efficiency and an outstanding reliability in a compact design, offers an investment with the most attractive CTO over the product life time. Not to forget the energy saving capabilities and low environmental footprint.

-

Highest thermal efficiency and close temperature approach

-

Compact units – space saving, easy to service and maintain

-

Maximum uptime – less fouling, stress, wear and corrosion

-

Flexible – easy to adapt to changed duty requirements

Plate types for different needs

Industrial line is available with four different plate configurations:

- Single plate with a chevron pattern design for parallel flow allows for optimum thermal performance and pressure drop.

- Single plate with a chevron pattern design for diagonal flow allows for optimum thermal performance through the heat exchanger when it is mounted horizontally and requires complete drainability.

- Double wall plate is used when extra care is needed to avoid mixing fluids.

Gemini double wall plate is used when extra care is needed to avoid mixing fluids in hygienic applications.

How it works

How it works

The heat transfer area of a gasketed plate-and-frame heat exchanger consists of a series of corrugated plates, assembled between the frame and pressure plates, which retain the design pressure. The sealing between the plates is made of gaskets. For the highest thermal performance and to enable a very close temperature approach, fluids normally run counter-currently through the heat exchanger.

The Industrial line is available with various pressing depths and angles of the chevron pattern and various shapes of the corrugation which are all carefully designed and selected to achieve optimal performance. The CurveFlowTM and the chocolate pattern distribution area are two design features available that ensure fluids are evenly distributed across the entire plate. The result is that the entire heat transfer surface is fully utilized and stagnant zones that can result in fouling are avoided.

High fllow turbulence between plates results in higher heat transfer; however, the consequence is pressure drop. Our thermal design engineers will help you design and select the model and configuration that is suitable for your application needs while delivering maximum thermal performance and minimizing pressure drop.

The Industrial line can be configured in different ways. The animation shows single pass configuration, but multi-pass with 2 or more passes on each side is also possible.

Alfa Laval gasketed plate heat exchanger – Flow principle

Flow principle of Alfa Laval gasketed plate-and-frame heat exchanger configured for single pass.

The principles and workings of gasketed plate heat exchangers

The concept behind a heat exchanger is relatively simple – heating or cooling one medium by transferring heat between it and another one.

In a gasketed plate heat exchanger, the plates are fitted with elastomeric gaskets which seal the channels and direct the media into alternate channels. The plate pack is assembled between a frame plate and a pressure plate, and compressed by tightening bolts fitted between these plates. The channel plates and the pressure plate are suspended from an upper carrying bar and fixed in position by a lower guiding bar, both of which are fixed to the support column. The design allows easy cleaning and simple capacity modification (by removing or adding plates).

The heat transfer area of a gasketed plate heat exchanger consists of a series of corrugated plates, assembled between a frame and pressure plates to retain pressure. Gaskets act as seals between the plates. Fluids normally run counter-currently through the heat exchanger. This gives the most efficient thermal performance and enables a very close temperature approach, ie the temperature difference between the exiting process medium and the entering service medium.

For heat sensitive or viscous media, co-current flow can be used to let the coldest fluid meet the hottest when entering the heat exchanger. This minimizes the risk of the media overheating or freezing.

Plates are available with various pressing depths, angles of chevron pattern and various corrugation shapes, all carefully designed and selected to achieve optimal performance. Depending on the application, each product range has its own specific plate features.

The distribution area ensures fluids are evenly distributed across the entire heat transfer surface and help avoid stagnant zones that may cause fouling.

While high flow turbulence between plates results in higher heat transfer, the consequence is pressure drop. Our thermal design engineers can help you design and select the model and configuration that is suitable for your application so that it delivers maximum thermal performance with minimum pressure drop.