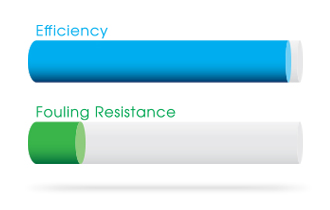

Brentwood offers the most complete line of counterflow film fills to fit any water requirements, from high-efficiency, cross-fluted fills to fouling-resistant, vertical fluted fill designs. These fills are complemented by industry-leading drift eliminators, louvers, nozzles, and a range of ancillary components engineered to improve cooling tower efficiency.

Overview

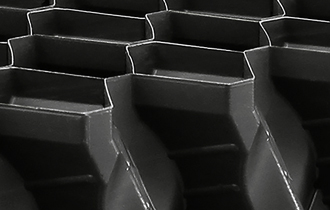

Brentwood’s AccuPac® Cross-Fluted Cooling Tower Film Fills improve water distribution by splitting the water stream as it descends through the cooling tower fill pack. The counterflow film fills feature a bonded edge with dedicated bond points for added strength and durability. The high thermal performance and low pressure drop are balanced by utilizing the engineered microstructure design and maintaining the highest manufacturing standards.

Brentwood has spent millions of dollars in R&D and testing of all cooling tower fill and drift eliminator products over the years, collecting results from thousands of high-performing installations. Whether your needs are for counterflow or crossflow tower applications, we can provide educated recommendations for the correct fill replacement to meet existing design criteria or improve upon older tower installations.

-

Material exceeds Cooling Technology Institute (CTI) Standard 136

-

Available with AccuShield technology

-

Select products available with Mechanical Assembly technology

Highly Efficient

Cross-Fluid fills offers the highest level of efficency of all fill film designs, improving heat transfer and maximizing overall tower performance.

Improved Water Distribution

The engineered microstructure incorporated into cross-fluted fills enhances water distribution and thermal mixing.

Dedicated Bond Points

Brentwood’s cross-fluted fills feature bonded edges for added media strenght and durability.

Beveled Tips

Beveled tips are incorporated into the cross-fluted design to promote drainage at the fill pack interfaces.